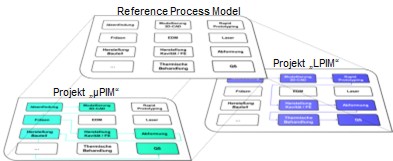

| Based on a 12 years experience, a reference process model for micro product engineering processes (µPEPs) in primary shaped microsystems technology has been developed. Based on this reference process model, know how on implementation of integrated µPEPs is available. This permits to manage the interactions between participating institutes needed to implement integrated µPEPs. In combination with the core-team-management approach all the institutions and skills needed to implement your project can be quickly and easily integrated. |

|

Design:

- Development: implementation and support of creative processes for product profile- and idea generation in a special creative laboratory (TRIZ-Box, 3D Power Wall, etc.) and subsequent implementation in 3D-CAD.

- Modeling, simulation and optimization of micro molding and µPIM processes, components and systems, robustness considerations

- Rapid Prototyping: application-oriented prototyping components made of metal alloys and ceramics by low-pressure powder injection molding (LPIM)

|

Production:

- Manufacturing:

- Micro powder injection molding of metallic (μMIM) and ceramic (μCIM) Feedstocks

- Two Component Injection Molding

- 3-axis and 5-axis milling

- μEDM methods (wire EDM, EDM-milling, EDM-sinking)

- Micro-casting of metal alloys

- μ-laser ablation

- Sintering and sinter joining

- Preparation processes + Process Characterization:

- Feedstock development

- Material and component behavior

- Mechanical properties, friction, wear

- Quality Assurance:

- Visual and tactile measuring methods

- scanning electron microscopy (SEM)

- Test rig technology (micro-gear-, gearbox-, bush bearing- and shaft-hub joint test rigs)

|